Product Description:

This Ridge Capping Roll Forming Machine is a powerful and efficient roll forming machine. With a Forming Speed of 20m/min and PLC Control System, this machine is designed to meet the high quality standards for

producing Ridge Cap. The metal sheets produced by this machine have high precision and

excellent surface finish, making it a perfect choice for mass production.

Features:

- Product Name: Ridge Cap Roll Forming Machine

- Type: Roll Forming Machine

- Drive Mode: Gear/sprocket

- Control System: PLC Control

- Forming Speed: 20m/min

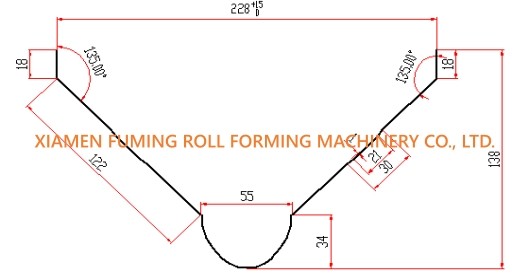

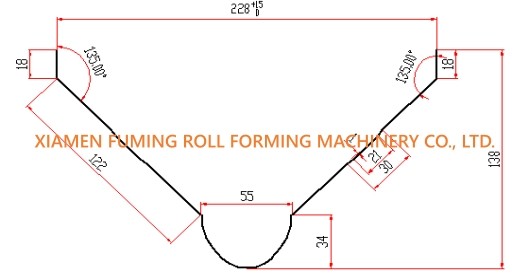

Drawing:

Technical Parameters:

| ROLL FORMING MACHINE FOR YX138-228 RIDGE CAP PROFILE |

|

| Material Specification |

| Thickness | 0.27mm-0.3mm |

| Material | GI |

| Strength | G550 or customized |

|

|

| Machine Components |

| 3Ton*500mm Hydraulic Decoiler |

| Coil inner hole expanding | Hydraulic system, 2.2KW pump motor |

| Speed regulating | Frequency inverter, 1.5KW motor |

| Expanding type | Taper wedge expanding system |

| Load capacity | Max.3Tons |

| Coil inner diameter | 510±30mm |

| Coil width | Max.500mm |

|

| Roll Forming Machine |

| Driving system | Gear/sprocket |

| Forming station | 18 stations |

| Roller material | 45# steel, hard chorme coated |

| Shafts Diameter | Φ75mm |

| Main motor | 7.5KW, frequency speed control |

| Line speed of rollformer | Approx. 20m/min or customized |

|

| Hydraulic Cutting Device |

| Cutting type | No Blanking cut |

| Cutting tool material | Cr12, heat treatment |

| Hydraulci pump motor | 4KW |

|

| PLC Control System |

| Function | Control quantity and and cutting length automatically |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider or Delta |

| Encoder | Omron |

| Cut-to-length tolerance | ≤±2mm or customized |

| Control Voltage | 24V |

|

| Product Rack | 4 meters×1 |

Applications:

This roll forming machine is designed to produce ridge cap for

roofing applications, and is suitable for installation in many

different kinds of building. It is also easy to operate and

maintain.

Support and Services:

Technical Support and Service for Roll Forming Machine

We provide comprehensive technical support and service for Roll

Forming Machine. Our team of experienced engineers and technicians

can help you achieve optimal usage of the machine and maximize its

performance.

- We provide professional installation and commissioning services.

- We provide remote and on-site technical support.

- We provide troubleshooting services and respond to customer

inquiries.

- We provide preventive maintenance services to keep the machine

running smoothly.

- We provide spare parts supply and repair services.

- We provide training and technical guidance.

If you have any questions or need technical support for Roll

Forming Machine, please don't hesitate to contact us. We are here

to help you.

FAQ:

Q 1: How can customers be assured that XIAMEN FUMING will deliver

qualified roll forming machines?

A 1: Customers can send their technician or entrust a third party

to XIAMEN FUMING’s factory to do machine inspection before

delivery.

XIAMEN FUMING can send their engineers to the buyer’s factory for

machine installation and commissioning.

Our roll forming machine is guaranteed for one year in correct

operation and maintenance.

Q 2: How does the customer install the machine when it arrives?

A 2: Our engineers will go to your factory for machine installation

and commissioning once you get your machine ready(including

electricity, testing material, hydraulic oil, auxiliary staff,

transport and lifting device, etc.), they will instruct your

technician how to operate the machine. Online supports including

video call will be provided if our engineers cannot visit your

place because of pandemic.

Q 3: Does XIAMEN FUMING provide customized roll forming machines?

A 3: Yes, we design and make roll forming machines according to the

latest market trend and the specific requirements suggested by

customers.